Optimizing Cut-off Saw Retrofit

Barr-Mullin Wonder Saw, Compu-Rip or Brute Retrofit

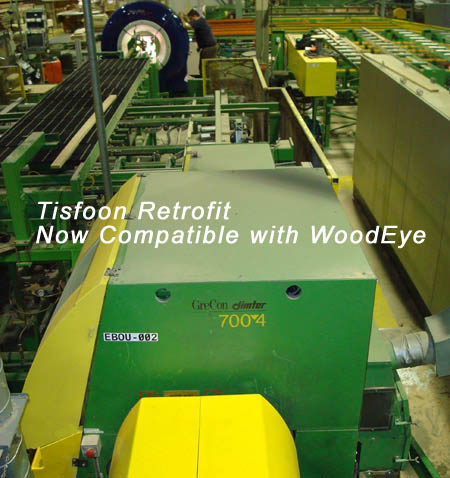

Grecon/Dimter Retrofit

Ultimizer Retrofit

Group 7,Dysis III Retrofit

"

At Vic Royal, we run two old optimizing saws with a new WoodEyeXC scanner. We cut short fingerjoint as well as long lineal in a number of widths and grades. SmartSaws control system has eliminated problems of sorting and blowing off waste, even when the waste piece is longer than the minimum fingerjoint. Our saws run faster than before and the interface software is easier to use. Service is very good, fast and efficient. We are happy with the SmartSaws retrofit and highly recommend them to everyone having to install a WoodEye Scanner without having to change their old saws.

"

- Nicolas Gagnon, Project manager, Industrial engineering Victoriaville Funeral Supplies Div. Vic Royal

With the price of steel going up and the abundance of used optimizing cutoff saws in the market, many companies are turning to us for state of the art (but used) saws to increase production levels and bring in scanners into their manufacturing process. Should you need to increase your production capacity, please know that we can help you there as well.

- Scanner compatibility (WoodEye, Luxscan, Lucidyne, Tisfoon, etc…)

- Superior Optimization Engine (at least 5 point yield gain!)

- "Smart Values". The computer adjusts values based on your incoming lumber grade and production requirements to give optimum yield while maintaining production requirements. No more over cutting or under cutting.

- Centering Cuts. Keep good parts away from defects by centering the solution.

- "Smart Stretch" feature shrinks defect marks by a user adjustable amount to reduce the effect of operator carelessness and crayon width giving more useable lumber.

- Grouping. Group like sizes to avoid confusion on the sorter line.

- First in first out job control. Enter all your upcoming orders and let the computer bring in cuts from the next order per your specifications.

- Eliminate drops in yield while transitioning from one job to another.

- Clear one face optimization. Using side marks, denote top face defects and bottom face defects to save yield where the part allows for defect on one side.

- Encoder based sorting.

- Eliminate erroneous sorts

- Multiple kick assignment for long boards, and multiple station assignment for high volume parts.

- Enhanced waste handling due to "SmartMove" logic. Special moves are performed to force a gap between pieces and eliminating trailing defect pieces behind good pieces.

- Minimize belt tension effects on sorting.

- Increased production

- Production is increased due to higher yields (more efficiency)

- Production is increased due to combining multiple defects in a row into a single longer defect.

- Production is increased due to not over cutting.

- Production is increased due to less re-cuts

- Production is increased due to less down time

- Industrial Motion Controller/Computer

- Increased cut accuracy due to "SmartAccel" smooth acceleration and deceleration.

- Delta Tau motion controller is the most advanced motion controller on the market and readily available off the shelf.

- Industrial Advantech PC communicating with the Delta Tau over ethernet

- Operator Friendly User Interface with Touch Screen.

- Multi-Language / Foreign Language Support

- Ability to have multiple users running different languages

- Optional Fast Saw Stroke Options

- Super fast hydraulic saw stroke breaks the production bottle neck to increase production!

- Super fast pneumatic stroke breaks the production bottle neck to increase production!

- Scanner compatibility (WoodEye, Luxscan, Lucidyne, Tisfoon, etc…)

- LumberID compatibility.

-

The LumberID system is a sure and unique way to eliminate queue control issues with scanners. Boards are "fingerprinted" at the scanner and then identified at each saw. There is no need for fancy material handling or "flushing" of the queue. Many man hours are saved and lumber is saved avoiding erroneous cuts. This system is $30,000 per station and easily pays for itself in less than 1 year. Each station consists of a computer, camera, and light source. One station is required at the infeed to the scanner and each cutoff saw will require a station for board identification. One popular demo we perform for the LumberID is to pre-scan 100 boards and then ask the prospective buyer to "pick a board, any board". When we re-scan the selected board, the hand written number of the board is displayed on the monitor.

©1994-2023 TUS, Inc. 3434 Edwards Mill Rd. Suite 112-326 Raleigh, NC 27612 USA